Flame-retardant Oxford cloth can be divided into pre-treatment and post-treatment flame retardant processes according to the production and processing methods. The production process of pre-treatment of flame-retardant Oxford cloth: add flame retardant, change the molecular structure, produce flame-retardant polyester chips and flame-retardant fibers, and then produce flame-retardant polyester yarn according to the requirements, and then plain weave , twill weave or large flower and other tissues are woven into fabric tissues, and then turned into flame-retardant Oxford fabrics through special production processes such as dyeing and coating.

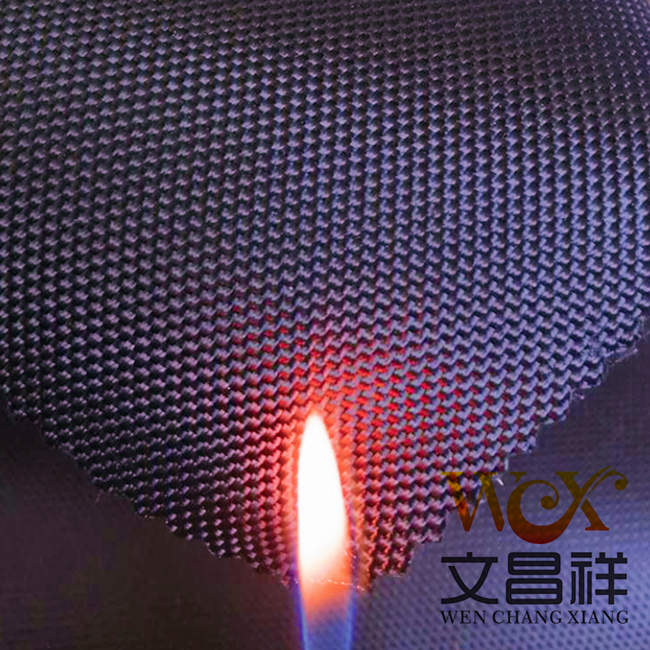

The flame-retardant oxford fabric produced by the pre-treatment process is soft to the touch, and the color and pattern are no different from ordinary fabrics; it produces a little white smoke when burned, and there are relatively few toxic gases; the flame-retardant oxford fabric made by the post-processing process has a fabric pattern, There are many kinds of colors to meet the personalized needs of customers. The price is lower than pre-treated flame retardant fabrics.

The post-processed flame-retardant Oxford fabric refers to the process of adding flame-retardant substances to the fabric after the completion of Oxford fabric production, soaking or flame-retardant coating processing, scraping or spraying. Fabrics with flame retardant properties.

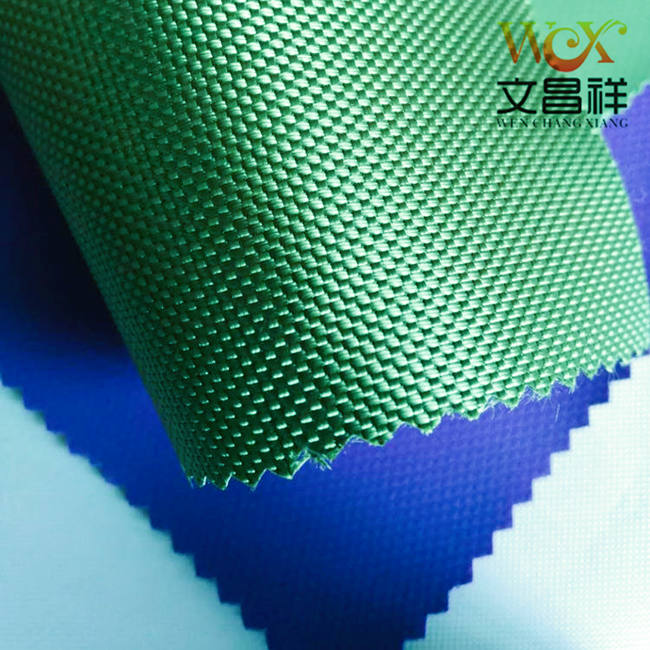

What are the specifications of Oxford cloth? Such as 1680D, 1200D, 900D, 600D, 420D, 300D, 210D, 150D and other Oxford cloth. Function classification of Oxford cloth: fire-retardant cloth, waterproof Oxford cloth, PVC Oxford cloth, PU Oxford cloth, camouflage Oxford cloth, fluorescent Oxford cloth, Printed Oxford cloth, composite Oxford cloth, etc.

</p