210D Oxford cloth: made of 200D yarn count plain weave on a water-jet loom, with a density of 15 *19, weight per square meter is 70. According to different post-processing processes such as dyeing, waterproofing, anti-velvet, windproof, anti-mildew, anti-UV, coating, printing, etc. (different post-processing processes for different uses), the weight will be different.

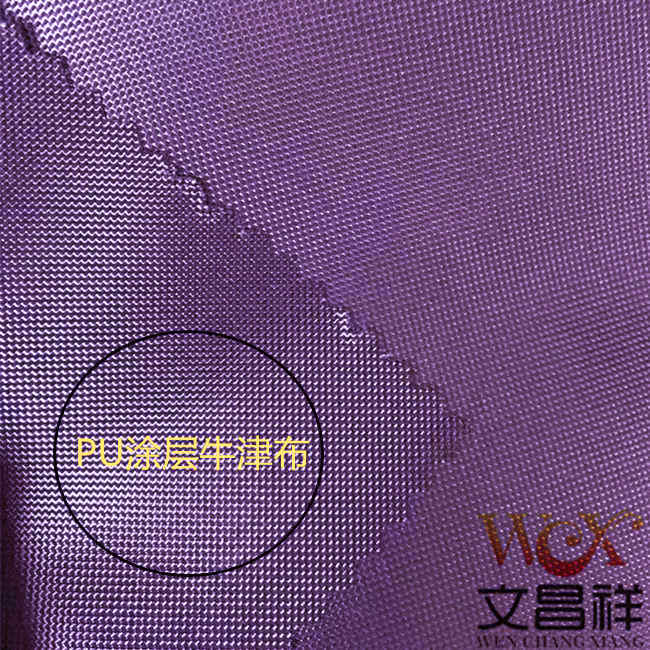

PU is a coating used in the post-processing process of Oxford cloth. It has low density, soft touch, strong wear resistance, flex resistance, good temperature resistance/breathability and other characteristics. Because PU Oxford cloth is very similar to real leather, it can be used as a substitute in all areas where real leather is used. It is economical and widely used in bags, shoes, sports, outdoor products and other fields.

PU Oxford cloth is waterproof and breathable, has a plump feel and a filmy surface. It has extremely excellent wear resistance, excellent breathability and aging resistance, is soft and comfortable, has strong flexibility and meets environmental protection standards.

210D Oxford cloth has excellent performance, light weight, breathable, delicate and soft, easy to wear Washes and dries quickly. There are many types of Oxford cloth products, and each category has its place of use. 210D Oxford cloth is suitable for lining fabrics such as tents, bags, shoes, rehabilitation equipment, outdoor sporting goods, and strollers.

What are the specifications of Oxford cloth? Such as 1680D, 1200D, 900D, 600D, 420D, 300D, 210D, 150D and other Oxford cloth. Function classification of Oxford cloth: fire-retardant cloth, waterproof Oxford cloth, PVC Oxford cloth, PU Oxford cloth, camouflage Oxford cloth, fluorescent Oxford cloth, Printed Oxford cloth, composite Oxford cloth, etc.

</p