The difference between Oxford cloth wet and dry coating lies in the primer and coating channel. Its glue surface solidifies under the action of water, and other physical test standards are consistent with it. Wet coating mechanically fixes polyurethane and adhesive on the surface of the fabric, which is environmentally friendly. The adhesive surface can be white, silver, transparent, black, etc. Wet coating process: the incoming fabric is inspected and passed—receiving the fabric—making it into a large roll—waterproofing—calendering—priming glue—passing the water trough—coating- –Water sink—drying—shaping—finished product inspection—packaging. After the waterproof oxford cloth wet coating process is completed, the following physical properties should be tested.

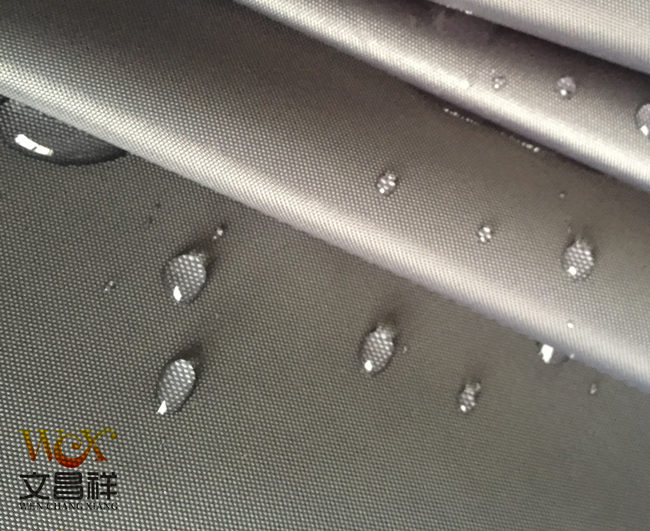

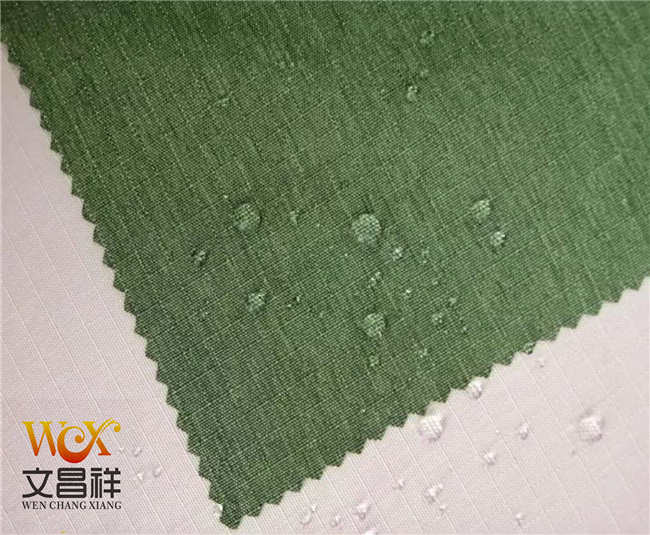

Waterproof: The American standard test AATCC-22 is 100 points (level 5) before washing, 90 points (level 4) after washing 10 times, and 80 points (level 3) after washing 20 times.

Tear strength: After multiple dry coating processes, especially calendering, the tear strength will be greatly reduced, which will weaken the wear resistance and damage resistance of the garment. If it cannot meet the tear requirements of the same variety, during the processing Consider adding an anti-tear agent to improve the tear strength of the fabric. Of course, this anti-tear agent is an environmentally friendly material. Coating uniformity: For fabric coating, put PU glue on the cloth surface and use a scraper to evenly distribute it. You can use a weighing machine to take a piece on the left, middle and right sides of the cloth and weigh it to know whether the values on the left, middle and right are qualified. .

What are the specifications of Oxford cloth? Such as 1680D, 1200D, 900D, 600D, 420D, 300D, 210D, 150D and other Oxford cloth. Function classification of Oxford cloth: fire-retardant cloth, waterproof Oxford cloth, PVC Oxford cloth, PU Oxford cloth, camouflage Oxford cloth, fluorescent Oxford cloth, Printed Oxford cloth, composite Oxford cloth, etc. </p