UV protection material types

UV protection material types

Research status of anti-UV shielding agents According to different protection mechanisms, the types of UV shielding agents used can be divided into two types.

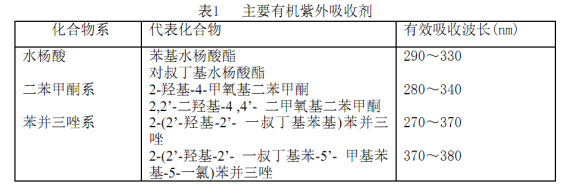

1. The mechanism of action of organic ultraviolet absorbers is mainly to absorb ultraviolet rays.

Organic ultraviolet shielding agents, or ultraviolet absorbers, refer to organic compounds that can absorb ultraviolet light with a wavelength of 270-400nm. What these organic compounds have in common is that they all contain hydroxyl groups in their structure, forming stable hydrogen bonds, hydrogen bond chelation rings, etc. In the process, energy can be absorbed and converted into heat energy for dissipation. Therefore, the energy transmitted into the polymer rarely plays a role in preventing ultraviolet rays. Commonly used in the domestic market are benzophenones and benzotriazoles, which are mostly used for fabric coating finishing.

Salicylic acid is rarely used due to its low melting point, easy volatilization, and absorption band biased towards the low band. Because there is a freely controllable reactive group – OH in benzophenone, it is more useful for ionic combination with fibers, but its heat resistance is poor. The photo-induced interconversion of benzophenone converts light energy into heat energy, and consumes the absorbed energy to return to the ground state energy level. It has little absorption of ultraviolet light below 280nm and sometimes tends to turn yellow. Benzotriazole is the preferred UV absorber due to its wide range of near-ultraviolet absorption. However, the compound itself does not have a reactive matrix and is generally adsorbed on the fiber surface in a single molecule state. This type of absorbent has a high melting point, low toxicity, and certain water dispersibility at high temperatures. Organic UV absorbers have insufficient heat resistance and may decompose over time. At the same time, their irritation to the skin must also be considered.

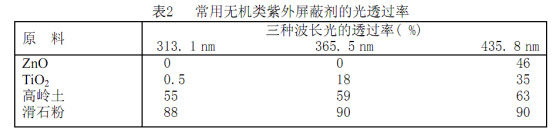

2. Inorganic UV reflectors, their main mechanism of action is to reflect UV rays.

Most UV shielding agents are metal oxides or ceramic powders, such as titanium dioxide, zinc oxide, talc, clay, calcium carbonate, etc. They all have high refractive index, and when added to fabrics, they can increase the reflection and scattering of ultraviolet rays on the fabric surface. Due to their high efficiency, safety and durability, inorganic UV blockers will not affect the style of fabrics when used on fibers, so they are attracting more and more attention. [1-3] Among them, titanium dioxide and zinc oxide have low ultraviolet transmittance and are more commonly used.

In recent years, due to the development of nanotechnology, the preparation of nano-TiO2 and nano-ZnO has become possible. At the same time, the UV shielding properties of the powder are further enhanced as the particle size decreases. Research on nano-TiO2-nano ZnO composite powder has found that the composite The UV shielding performance of the system is better than that of a single system.

Production method of anti-UV fiber and performance of anti-UV additive

Disclaimer:

Disclaimer: Some of the texts, pictures, audios, and videos of some articles published on this site are from the Internet and do not represent the views of this site. The copyrights belong to the original authors. If you find that the information reproduced on this website infringes upon your rights, please contact us and we will change or delete it as soon as possible.

AA