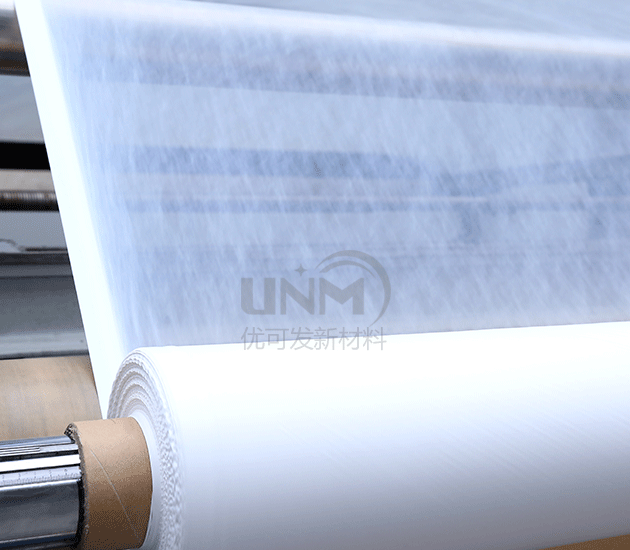

Polytetrafluoroethylene film is made from polytetrafluoroethylene and is expanded and stretched to form a microporous film. This film is coated on various fabrics and substrates using a special process to become a new type of filter material.

PTFE can also be sprayed on the surface of various household kitchenware, which can reduce the accumulation of food, grease and dirt, making it easy to clean. And the purpose of improving food quality, such as making woks, frying pans, baking pans and molds for various pastries, etc. Polytetrafluoroethylene cooking utensils can be used at room temperature, but chemical changes will occur after the temperature reaches 260°C. It will begin to decompose when the temperature is higher than 350°C. If empty cooking utensils are placed on the fire, it will easily exceed the temperature limit. This temperature will destroy the coating and produce harmful substances.

The currently commercialized membrane material is perfluorosulfonic acid membrane. Although it has excellent chemical stability and good proton conductivity, it is expensive and harmful to the environment. The strong dependence on water and temperature leads to its practical application effectiveness. Due to the excellent properties of PTFE membrane, it becomes a good substitute for perfluorosulfonic acid membrane. Generally, there are two relatively simple and feasible methods: A. Surface deposition method: that is, using the PTFE membrane as the base and filling the holes with electrolyte; B. Radiation grafting method: under the action of ionizing radiation, several active points are generated on the surface of the PTFE membrane. Vinyl monomers or their homopolymers are then grafted onto these active sites.

Polytetrafluoroethylene film technology has always been the core of business, in biopharmaceuticals, equipment, food and beverages, semiconductor processes, It plays an indispensable role in many fields such as communications. Its pore-forming capacity ranges from 0.1μm to 1μm, providing functional solutions such as fine filtration, removal of small bacteria and viruses, hydrophobic breathability, and sound transmission. Interested parties can enter the store for consultation and purchase!

</p