Preparation of wave-absorbing coating composite fabric and its wave-absorbing properties

Preparation of wave-absorbing coating composite fabric and its wave-absorbing properties

Based on the single-layer absorber transmission line theory and combined with computer-aided design, appropriate absorbing powder is selected, copper-nickel plated fabric and metal yarn blended fabric are used as the base fabric, and polyurethane is used as the matrix to prepare a coating thickness of 1. 5 mm. of flexible textile coated composite fabrics. The electromagnetic properties of the absorbing powder were tested and analyzed, and the influence and mechanism of different mixing ratios of the absorbing powder and the matrix and the base fabric on the reflection loss in the range of 2. 6 to 18. 0 GHz were investigated and analyzed. The results show that within a certain range, as the volume fraction of absorbing powder increases, the absorbing efficiency increases, the frequency band broadens, and the peak of the reflection loss curve moves to low frequency. The wave-absorbing effect of coated fabrics based on metal yarn blended fabrics is better than that of coated fabrics based on copper-nickel plated fabrics.

With the rapid development of electromagnetic wave shielding and absorbing material technology, people have put forward higher requirements for absorbing materials, namely wide, light, thin and strong. Improving the electromagnetic wave absorption rate is the goal of absorbing materials. The design of absorbers mainly includes: absorbing efficiency design, bandwidth design, shape and thickness design. During the design process, its application value and cost need to be considered, and it is often difficult to balance width, lightness, thinness, and strength. The design of current absorbers is completed through continuous adjustments and improvements through experiments under the guidance of existing theories. Under the guidance of transmission line theory and combined with computer-aided design, acetylene carbon black with low density and price is selected, which has a good absorbing effect on high frequencies, and carbonyl iron powder with high magnetic loss rate is selected, which has good absorbing effect on low frequencies. It has good wave absorption effect, but its high density may limit its application in some fields. The research and development of textile absorbing materials has also become a research hotspot. Non-woven fabrics are used as base fabrics and composite laminated structures are used to prepare non-woven fabric-coated absorbing materials. By controlling the composition of the absorbing coating and designing a reasonable laminated The layer structure improves the material’s wave-absorbing performance and effectively reduces the surface density of the material.

Yu Mingxun et al. used imitation papermaking devices and wet spinning processes to prepare centimeter-wave/millimeter-wave compatible invisible wet-woven fabrics, and studied the absorbing properties of the invisible wet-woven fabrics in the 8-12 GHz and 30-40 GHz frequency bands. E. Tan et al. discussed the effects of different combinations of multi-layer fabrics with ceramic fiber as the base fabric and silicon carbide as the base and different oxidation degrees on the fabric’s ability to absorb electromagnetic waves. They believed that in the gigahertz range, the fabric has a good ability to reduce reflection and transmission. The effect is that it can absorb more than 90% of electromagnetic waves. In view of the absorbing and spinnability properties of iron fiber, its microscopic morphology, mechanical properties and friction properties were studied to predict the operability of smooth spinning of iron fiber absorbing materials. This paper uses copper-nickel plated cloth and metal yarn blended cloth as the base cloth, taking advantage of its advantages of low surface density, thin thickness, good flexibility, etc., by coating absorbing agent on the base cloth, focusing on studying the mixing ratio of absorbing powder. changes and the influence of base fabric on the wave absorption performance of coated fabrics.

1 Sample preparation and test methods

1. 1 Raw materials

The test base fabric is copper-nickel plated cloth (polyester filament woven fabric, thickness is 0. 08 mm, surface density is 70 g/m2); metal yarn blended fabric (30% 302 stainless steel metal fiber + 40% cotton + 30 % polyester, thickness 0. 3 mm, area density 180 g/m2). PU binder; coupling agent; diluent DMF, diluent toluene; dispersant OP-7; absorbing powder acetylene carbon black (ACB), density is 0. 067 g/cm3; absorbing powder carbonyl iron (CIP ), the density is 3. 7 g /cm3.

1. 2 Preparation of specimen

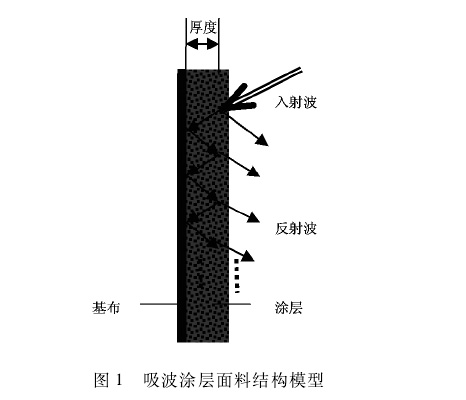

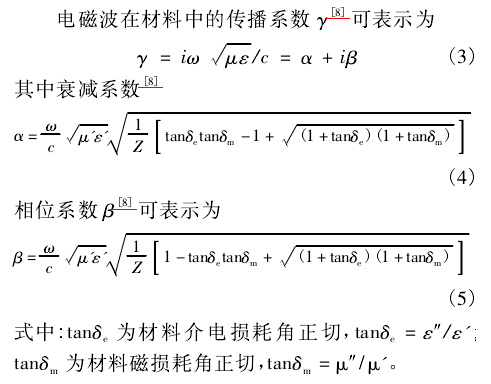

Add different proportions of absorbers (acetylene carbon black, carbonyl iron) to the diluent DMF-toluene and dispersant OP-7, stir for 10 minutes with a JB500D electric mixer, add the binder PU (solid content is 30%) and then use The electric mixer was stirred at a speed of 1500 r/min for 60 min to prepare the absorbing coating. Adjust the absorbing coatings with different proportions of absorbing agents to appropriate viscosity, use a coating prototype to coat copper-nickel plated cloth and metal yarn blended fabric with corresponding thicknesses, and cure in an HD101A electric blast oven. Apply multiple times to achieve the desired thickness to obtain the desired absorbing coating fabric. The structural model of the designed single-layer absorber is shown in Figure 1. In the model, the base fabric serves as an electromagnetic wave shielding material and is regarded as an ideal conductor, so that the boundary between the base fabric and the coating only reflects but does not transmit. The basic requirement for the absorbing coating fabric to absorb electromagnetic waves is to meet the impedance matching principle and the maximizing attenuation principle. The input impedance formula is based on the premise that the base fabric Figure 1. The structure model of the absorbing coating fabric can be regarded as an ideal conductor. According to Electromagnetic wave transmission theory, the reflectivity formula of the interface between a single layer of absorbing material and air: d is the thickness of the absorbing material; λ0 is the wavelength of electromagnetic waves in vacuum or the wavelength of electromagnetic waves in free space; ε’ and ε″ are relative The real and imaginary parts of the complex permittivity; μ’ and μ″ are the real and imaginary parts of the relative complex permeability. The propagation coefficient γ of electromagnetic waves in materials uses the absorber transmission line theory and multi-objective optimization calculation method of equations (1) to (5) to develop an optimal design software for absorbing materials. The absorbing powder and absorbing powder can be imported into the software. Establish a database for the electromagnetic parameters ε’, ε″, μ’, μ″ of the binder, and enter the expected coating thickness, �Cost improvement. When the volume fraction of carbonyl iron powder reaches 40%, the frequency band with reflection loss less than -6 dB ranges from 10. 9 GHz to the measurable high frequency band, and the small reflectivity reaches – 22. 6 dB. Regarding the absorption of electromagnetic waves, carbonyl iron powder mainly produces through polarization effect and natural resonance. Natural resonance is the main mechanism of its wave absorption. It is speculated that the increase in the volume fraction of carbonyl iron powder will cause the peak value of its reflection loss curve to move to low frequency.

2. 3. 2 Analysis of the influence of base fabric on the absorbing performance of coated fabrics. Figure 6 shows that the trends in the absorption curves of copper-nickel plated base fabrics and metal yarn blended fabric absorbing coated fabrics are basically the same. Compared with copper-nickel plated base fabric (CNCF), the frequency band where the reflection loss of metallic yarn blended fabric (MYBF) coated fabric is less than -6 dB is wider, the small peak point of reflection loss is lower, and the reflection loss curve moves toward the low frequency direction. Around 3 GHz. There are certain differences in the shielding properties of these two types of conductive base fabrics. The metal yarn blended base fabric draws stainless steel fibers into filaments to form a grid structure inside the fabric. This kind of stainless steel fiber mesh can shield electromagnetic waves. When the aperture of the stainless steel mesh is less than one quarter of the wavelength of electromagnetic waves, it can effectively shield electromagnetic waves. Its shielding effectiveness is related to the diameter, spacing and resistance of the metal wire per unit length. The copper-nickel coating base fabric is coated on the textile by vacuum evaporation or magnetron sputtering.

Then a copper-nickel metal layer is plated using a composite plating process to form a metal film and mesh on the cloth base, both of which have holes. Research by Shi Meiwu et al. shows that the size, shape and spacing of holes have an important impact on the shielding effect of textiles. The copper-nickel plated base fabric has complete reflection, small hole size, good conductivity, and higher shielding efficiency than the metal yarn blend base fabric. cloth. It can be seen that the shielding effect of the metal substrate has little impact on the absorbing performance of the absorbing material. However, compared with the copper-nickel plated base fabric, the electromagnetic parameters of the 302 stainless steel fiber blended base fabric in the frequency range of 2 to 18 GHz are consistent with the spectrum response characteristics of the absorber. According to the requirements, the metal yarn blended base fabric itself has certain wave-absorbing properties, which has exceeded the shielding effect of the metal substrate and becomes an electromagnetic wave absorbing layer. The absorption loss curve of the coated fabric is biased towards low frequency, which may be due to interface polarization. The absorbing paint and the metal yarn blended base fabric are more likely to bond. The paint is fully filled into the pores between the yarns and is firmly combined with the hairiness of the yarn. ,

The two base fabrics also have holes for resin to penetrate into the yarns of the fabric, but the holes of the metal yarn blended base fabric are much larger than the copper-nickel plated base fabric, making the filling rate and contact area between the paint and the metal yarn fabric larger than that of the copper-nickel plated base fabric. Copper-nickel coated fabric, a large number of electrons gather at the interface between the base fabric and the coating, which significantly enhances the wave absorption effect. Conclusion The reflection loss trend of the absorbing coating fabric was simulated using the absorber transmission line theory and multi-objective optimization calculation method. An absorbing coating fabric with a thickness of 1. 5 mm was prepared. Acetylene carbon black and carbonyl were measured and analyzed. The electromagnetic properties of iron powder, compared the performance of copper-nickel plated conductive base fabric and metal yarn blended base fabric, studied the effect of acetylene carbon black and carbonyl iron powder and their mixing ratio on the material’s wave absorption performance, and the effect of the base cloth on the wave absorption Performance impact.

The results show that acetylene carbon black has good electrical loss performance. As its volume fraction increases within a certain range, the effect of reflection loss is enhanced. The peak value of the reflection loss curve moves to low frequency, and the absorption frequency band is broadened. The electromagnetic properties of carbonyl iron show Its good magnetic loss characteristics. The difference in the base fabric also leads to differences in its absorbing effect. After coating, the metal yarn blended fabric has a wider frequency band with a reflection loss less than -6 dB, a lower reflection loss peak point, and a lower reflection loss than the copper-nickel plated base fabric. The peak of the curve moves toward low frequency by about 3 GHz. The research results of this article provide certain reference for the selection of coating base fabric. sdfwefwegre

Disclaimer:

Disclaimer: Some of the texts, pictures, audios, and videos of some articles published on this site are from the Internet and do not represent the views of this site. The copyrights belong to the original authors. If you find that the information reproduced on this website infringes upon your rights, please contact us and we will change or delete it as soon as possible.

AA