What fiber has its own cooling effect?

Which fiber has super thermal insulation properties?

Is there a fiber that can change temperature?

Isn’t it magical that fiber can increase oxygen carrying capacity?

Come, the editor will open your eyes!

A fiber with a cooling feel

In recent years, with the advancement of technology and the further reduction of fiber costs, the application and development of high molecular weight polyethylene fibers in the civilian field has entered the field of express applications. Fabrics woven from this fiber have obvious It has a cool feeling and is durable. It is widely used in mattresses, cushions, mats, ice sleeves, sportswear and other fields. Due to its cool and skin-friendly tactile feeling, it brings a new life experience to consumers.

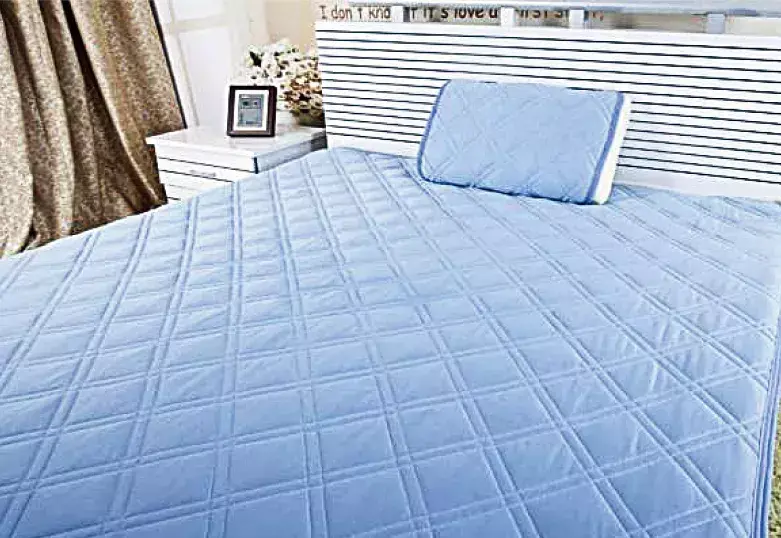

Mattresses made of high molecular weight polyethylene fiber

Polyethylene fiber, also known as ethylene fiber, is a type of polyolefin fiber. The material itself has a high thermal conductivity rate and can quickly dissipate heat. It is often used as a cooling material.

Using this fiber material to make fabrics feels silky and has the effect of imitating silk. At the same time, the material itself has a stable chemical bond structure, a certain degree of hydrophobicity, and antibacterial and mildew-proof functions. It is a new fiber material with excellent comprehensive properties.

The polyethylene composite fiber produced by Kaitai Special Fiber Technology Co., Ltd. is made by composite co-spinning of high molecular weight polyethylene and other fibers. , improves the softness of the fiber itself, while ensuring the coolness of the fiber, and has passed professional cold-temperature testing certification. In addition, the application of composite spinning technology can make the fabric have a satin effect, increasing the richness and selectivity of the product.

High-weight polyethylene fiber products

Mattresses and mats made using this product can reduce the indoor air conditioning temperature by 1℃~2℃ in hot summer. Studies have shown that every 2°C increase in temperature during air conditioning cooling can save 7% to 8% of electricity bills and reduce 800g of carbon emissions, thus achieving the effect of energy conservation and environmental protection.

Sportswear made of this fiber will produce an instant cooling temperature of 1℃~2℃ when it comes into contact with the skin. Irradiation will produce a cooling temperature difference that lowers the body surface temperature by 3°C to 4°C, which can significantly reduce the sweat rate and feeling of stuffiness, and relieve fatigue.

A kind of Kevlar fiber with super thermal insulation performance

Hollow fiber and ultrafine fiber are fibers with better thermal insulation properties among chemical fibers. Through research on them, it is found that the thermal insulation performance of fiber materials is directly proportional to the still air content inside the fiber materials, and is proportional to the content of still air inside the fiber materials. Diameter size is inversely proportional to overall material density.

Aerogel fiber has significant characteristics such as extremely high porosity and ultra-low density. In theory, it has the best thermal insulation effect A kind of fiber that is expected to replace microfiber and even subvert down. It is the most important development direction of the next generation of thermal fiber. However, the high porosity characteristics of aerogels also cause great challenges in their preparation.

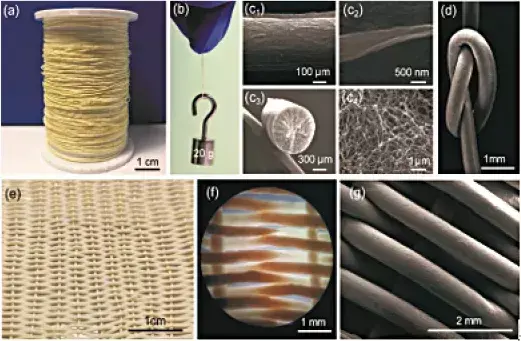

Aerogel fiber

Aerogel fiber

Based on this Zhang Xuetong, a researcher at the Suzhou Institute of Nanotechnology and Nanobionics, Chinese Academy of Sciences, and his aerogel team obtained a nanofiber dispersion by dissolving DuPont™ Kevlar fiber, and then carried out wet spinning, special drying and other processes to prepare a high-performance Kevlar airgel fiber with porosity (98%) and high specific surface area (240m2/g).

The airgel fiber has excellent mechanical properties and can be bent, knotted, woven, etc.; it has excellent thermal insulation Performance, the thermal conductivity at normal temperature is only 0.027W/m·K, and its thermal insulation performance at low temperatures is 2.8 times that of cotton. It can perform thermal insulation performance for a long time in extreme environments of -196℃~300℃; it has It has excellent chemical stability and can be modified in various ways such as dyeing, hydrophobization, and electroless plating without damaging the main skeleton structure of the airgel.

Importantly, the airgel fiber can also be prepared into air-conditioning fiber by filling phase change materials, and its thermal enthalpy value can be Reaching 162J/g, far exceeding the performance of existing commercial Outlast air-conditioning fiber�Enthalpy value.

A fiber that makes clothes warm on their own

In life, when ordinary close-fitting clothes are first put on, the human body feels cold. This is because there is a hot and cold temperature difference between the skin and the clothes, resulting in heat conduction. The clothes are often covered with the body, especially when Distressing and uncomfortable on a winter morning.

Is there any way to solve this problem? At the 2019 China Brand Day event, Shanghai Zhengjia Milk Silk Technology Co., Ltd. demonstrated a type of Yirebao fiber that can make clothes warm by themselves.

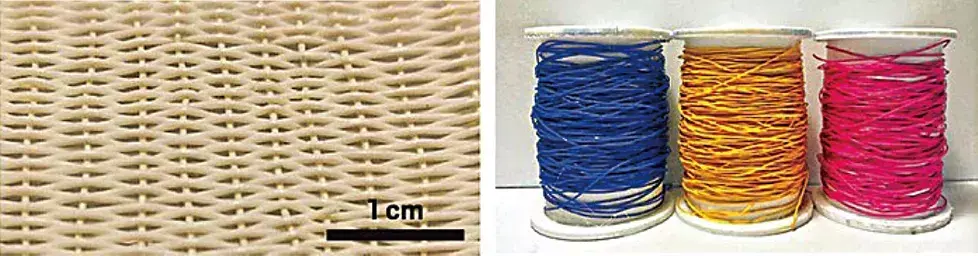

Yirebao fiber and products 1

Yirebao fiber and products 2

Yirebao fiber is a kind of modified acrylic fiber with high moisture regain. It introduces a large number of hydrophilic groups such as -OH, -NH3, -COOH, -CONH, etc., and has high hygroscopicity. At a temperature of 20℃ At a relative humidity of 65%, the moisture absorption capacity is about 3.5 times that of cotton.

At the same time, the fiber can repeatedly absorb and release moisture (breathing) cycles according to the environment for a long time. It absorbs moisture and generates adsorption heat at the same time. That is, it can heat itself after absorbing water. Therefore, this fiber can allow the fabric to absorb moisture (trace moisture) emitted by the human body to generate heat, speed up the balance of temperature between the skin and clothing, and ease the temperature difference between the two. In addition, Miaoka’s extremely high moisture absorption performance can prevent the cold feeling after sweating, keeping the clothes dry, comfortable and warm for a long time.

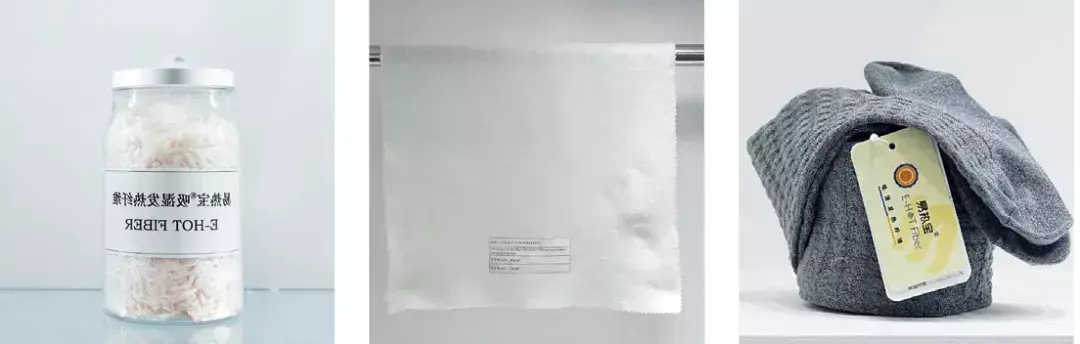

A fiber that captures heat and increases oxygen carrying capacity

Recently, the famous sports brand Under Armor launched a sportswear series “Rush” made of high-tech fabrics. This new fabric uses Celliant® patented technology, which weaves natural mineral components with clothing fibers. It can effectively capture the heat released by athletes and retransmit the energy back to the athletes through far-infrared rays, thereby improving their sports performance. .

The ultimate goal of the entire energy exchange process is to expand blood vessels and improve the body’s oxygen-carrying capacity, aiming to provide athletes with better performance during competition and training Provide a small nudge along the way.

Under Armor rush series 1

Under Armor has always been committed to helping athletes through the combination of science and technology. In 2018, Under Armor launched a “TB12 sports recovery pajamas” that uses active ingredients in the fiber to help the body recover physical fitness, and then launched a series of post-exercise physical recovery clothing. This time the Rush series once again uses high-tech fabrics to allow athletes who wear Rush to quickly recover and improve.

Under Armor rush series 2

Oxygen is the most important factor for athletes to recover physical fitness, get adequate sleep and achieve excellent sports performance. Rush can increase the oxygen carrying capacity of the blood for the wearer, thereby improving performance. Effect. At present, Under Armor’s endorsed athletes have begun to wear Rush series sportswear for training and competition. These athletes’ projects cover football, rugby, volleyball, weightlifting, fighting, etc.

Many athletes who have tried it on have already given preliminary feedback on Rush clothing. After wearing Rush sportswear for daily training, some athletes do feel that their muscles are not as sore as usual.