One wave is not over, but another wave is rising!

Nearly a hundred leading chemical companies “jointly” stopped production! The chemical market, which is already imbalanced between supply and demand, is even worse! A new round of price increases may begin! It is understood that nearly a hundred chemical companies are currently shutting down for maintenance or planning to shut down for maintenance this year, involving PTA, bisphenol A, PC, PP, PE, PVC industry chain and many other chemical products. Some of these companies perform partial equipment maintenance, while others perform complete shutdown maintenance, and the cycle is generally long, basically between 10 and 50 days. Some companies directly announced that they will cut off supply! There is not much inventory left, so be ready to stock up!

The specific maintenance situation is as follows:

Leading leaders reduce April contract volume, many PTA announce maintenance equipment

PTA will usher in a large-scale maintenance window in April, and PTA is available in stock The business environment is booming. On March 24, some PTA suppliers announced the implementation of reductions in April contracts: Yisheng announced that the April PTA contract will be supplied at 80% of the annual contract quantity; Hengli Petrochemical’s April PTA contract will be supplied at 70% ; A supplier in South China plans to reduce the contract volume in April, and the specific reduction situation is being negotiated; a supplier in East China will supply 50% of the contract volume in April, etc.

At the same time, other PTA factory installations are rushing to announce maintenance.

The major polyethylene PE factory has been undergoing maintenance for 45 days!

Domestic PE equipment maintenance is relatively concentrated in March. Shenyang Chemical, Yanshan Chemical, Qilu Petrochemical, Dushanzi Petrochemical and other companies have arranged shutdown maintenance plans. The duration ranges from one week to 40 days, and the affected output is nearly 200,000 tons/year.

Maoming Petrochemical 2# LDPE unit maintenance has been postponed to On March 24, its 350,000 tons/year HDPE will also be stopped around the 24th. The PE shutdown of Maoming Petrochemical affects 81,800 tons/year.

22 PC companies have confirmed that their installations will be shut down for maintenance

At present, domestic manufacturers only have Lihuayi Weiyuan’s 130,000-ton/year PC device maintains full-load operation, while the operation of other domestic devices has declined or stopped.

Covestro, Lotte Chemical, LG Chemical, Shanghai Mitsubishi, Sinopec Mitsubishi and other domestic and foreign companies have arranged shutdown maintenance plans for more than a month this year.

Bisphenol A will be shut down for maintenance for about 45 days

Not only will PCs undergo major overhauls this year, but upstream bisphenol A products also have maintenance plans from March to May, with some shutdowns lasting up to 45 days.

Butadiene companies parked for up to 40 days

Fushun Petrochemical’s butadiene and downstream rubber unit shutdown time is determined to be around April 12, and the shutdown time is initially expected to be around 40 days; Zhenhai Refining and Chemical 165,000 The maintenance time of the ton/year butadiene unit has been postponed from the initial March to April, and the latest news may be postponed to the second half of May.

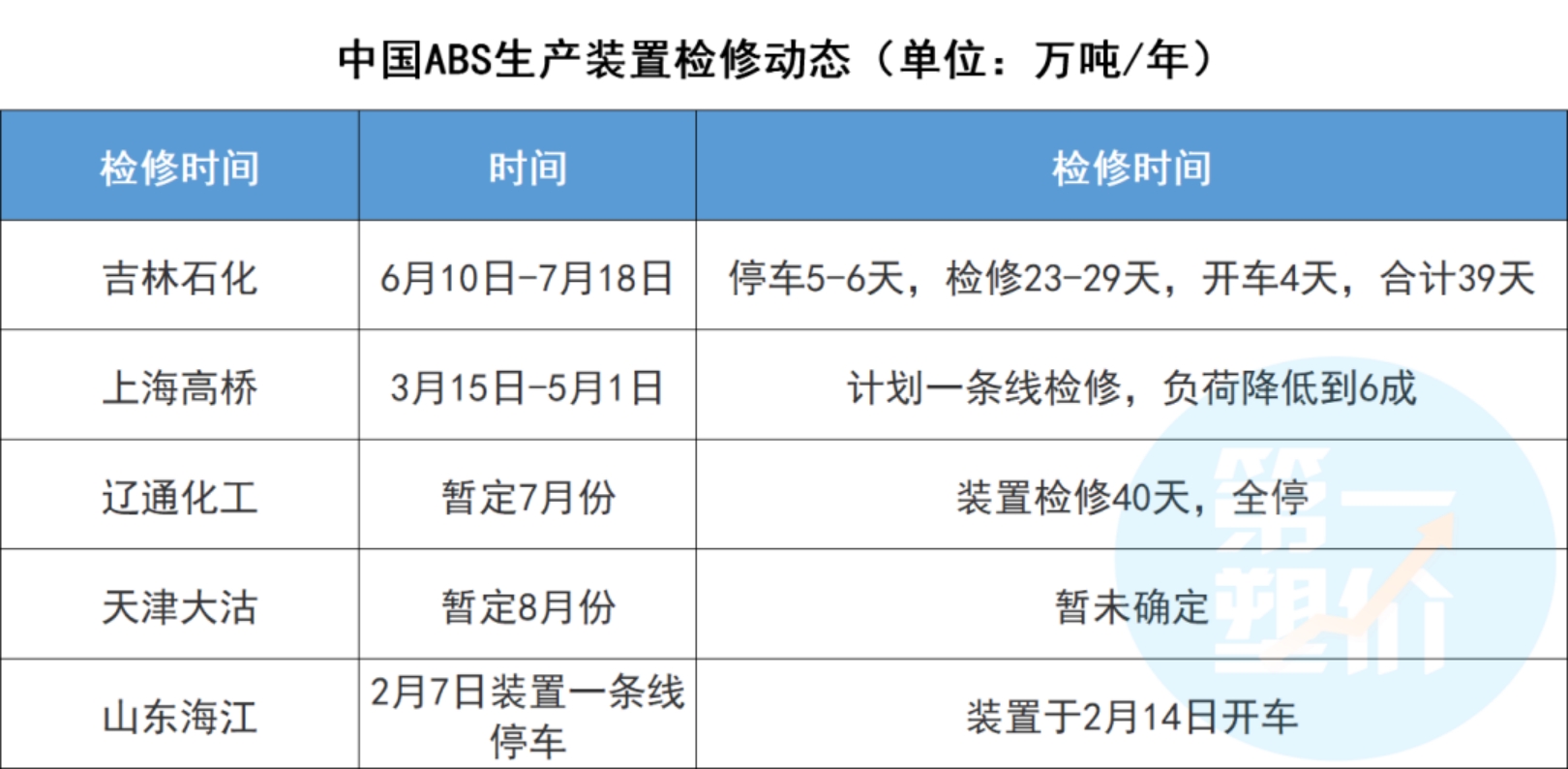

ABS Enterprise will park for 40 days

Shanghai Gaoqiao plans to shut down a production line for maintenance from mid-to-late March, which will last about 45 days. Jilin Petrochemical plans to shut down all lines for maintenance from the end of May to early July. The overall loss is estimated to be around 60,000 tons.

Styrene shutdown for maintenance lasts for 50 days

Panjin Bora 350,000 tons/year installation It is planned to shut down for maintenance for 20 days on April 1; Dongfang Petrochemical’s 120,000 tons/year unit will be shut down on March 3 and is scheduled to be inspected for 45 days; Yanshan Petrochemical’s 80,000 tons/year unit is scheduled to be inspected for 50 days in late March. ; Ningbo Daxie’s 360,000 tons/year unit plans to shut down for maintenance for one and a half months at the end of March, and reduce the load to 70% starting from the beginning of March.

In the upstream and downstream game, who can’t bear it first?

At present, with the increase in maintenance of major factories, the supply of raw materials may become more tense. In addition, chemical giants such as BASF, Dow, Tenox, and Chemours have It has been “respected to go up first”, and a new round of price increases seems to be inevitable.

This round of price increases is also the trend of the general environment. Central banks around the world are releasing water. Inflation expectations will definitely be reflected first in the price increases of commodities. On March 14, Tao Chuan, chief macro analyst of Soochow Securities, believed that “this is the fastest rise in commodities since the 21st century.”

But in fact, this round of surge in raw materials still has a price but no market. Factories usually reserve raw materials several months in advance before the Spring Festival holiday. Therefore, in this post-holiday price increase, some downstream companies are still “watching the excitement” and waiting for price cuts before replenishing supplies.

If this state of price but no market continues, upstream companies willThe industry’s inventory will be overstocked, and when it reaches a certain level, they will cut prices to increase sales. Some bosses believe that once the price is reduced, the drop will be larger. Let’s see now, in the end, it’s the downstream that can’t handle the orders, or the upstream that can’t handle the exchange!

However, judging from the current situation, there is still support for the chemical market to continue to rise. This price increase of raw materials may continue for another 3-6 months!

First, the World Bank predicts that the global economy will grow by 4% in 2021. The prospects for global economic recovery are relatively optimistic, with strong demand for chemicals and other bulk commodities. As the economy resumes growth, companies’ initiative to replenish inventories will increase demand for commodities from the real economy and provide support for their price increases.

Second, countries around the world have not completely withdrawn from the quantitative easing monetary policy plan in the short term, and the Biden administration’s $1.9 trillion active stimulus plan has also been officially implemented. , inflation exceeded expectations and further expanded from financial channels to demand for commodities.

</p