The white embryo of Oxford cloth can be made into various colors through post-finishing process (dyeing process), and the other one is yarn-dyed fabric. The simple understanding of yarn-dyed fabric is that it is woven with colored yarn.

Yarn-dyed fabric Oxford cloth has rich patterns, fine distribution of color points on the cloth surface, coordinated colors, pure colors, bright tones, clear layers, and strong three-dimensional effect. It has a wide variety and each has its own characteristics. Because it is woven from raw yarn after dyeing, it has good color fastness.

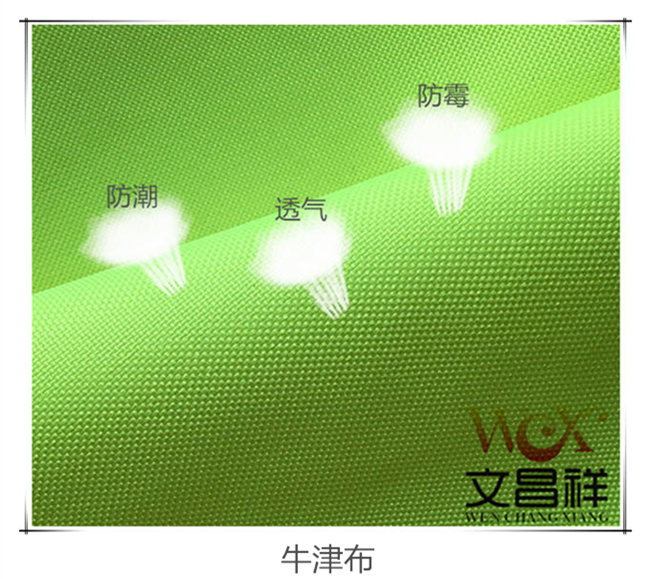

Different products can obtain special properties through post-finishing processing, such as oil resistance, waterproofing, hygroscopicity, breathability, heat protection, flame retardant, fire retardant, antistatic, bacteria release, and radiation release. Anti-static, anti-melting, etc.; mainly used in decorative fabrics, bags, clothing linings, industry, etc.

Yarn-dyed fabric Cloth quality improvement generally requires post-finishing processing.

a. Improve hand feel finishing: sizing finishing (hard feel), soft finishing (soft feel), and imitation wool, silk, linen, etc.

b. Improve processing performance, dimensional stability and finishing: mainly including tenter finishing, heat setting finishing, resin finishing, pre-shrinking finishing, etc.

C. Improve appearance finishing: such as whitening finishing, calendering finishing, etc.

D. Finishing to improve wearing performance: It can be finished through physical and chemical methods to make the fabric have various properties.

Learn more: For details about Oxford cloth, please consult textile customer service or call the hotline: 400-8380917.

</p