Fire retardant fabrics have received close attention from countries around the world. In particular, there are strict requirements on the performance, standards and environmental protection of fire-resistant and flame-retardant textiles. There are two methods commonly used in my country to evaluate the performance of flame retardant fabrics.

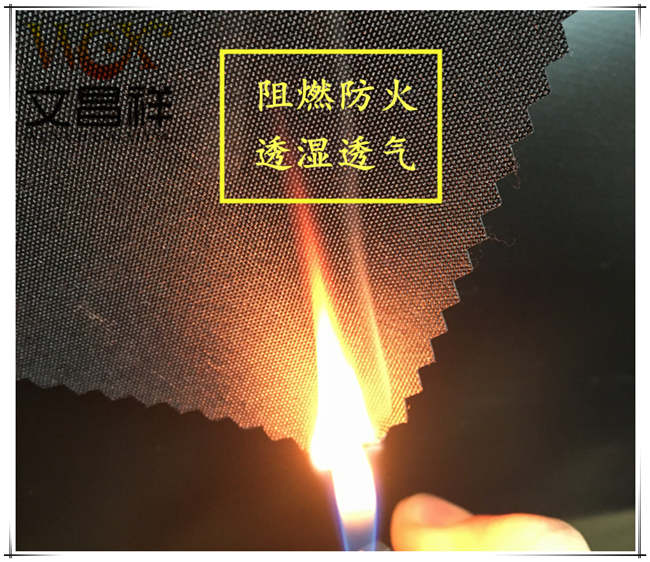

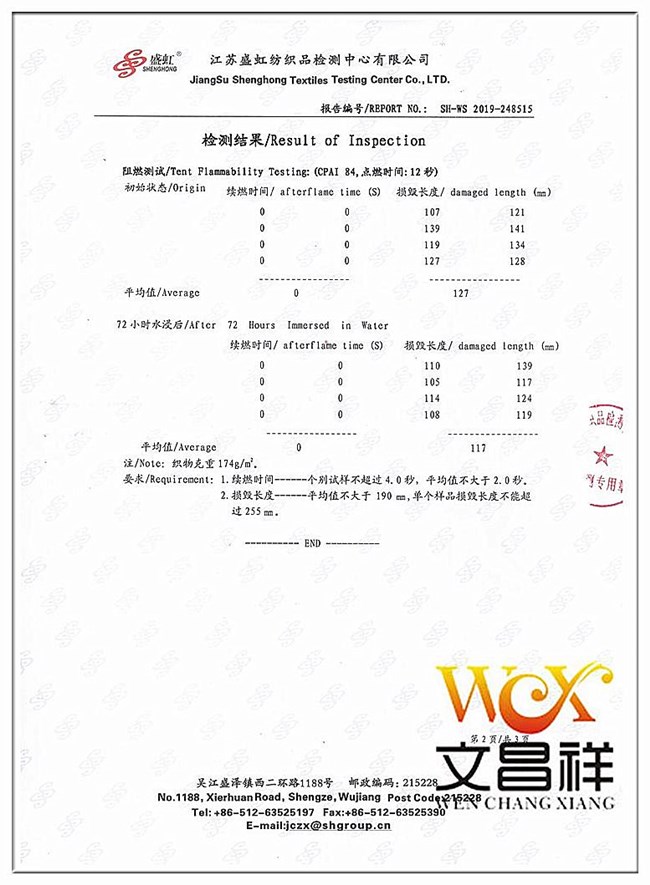

Method 1 : The fire-proof and flame-retardant Oxford fabric that has undergone special fire-proof and flame-retardant technology is in contact with the flame in the specified method. The shorter the flaming burning time and the flameless burning time within the specified time, the lower the degree of damage, which means that the fabric is damaged. The better the flame retardant performance, and at the same time, if the flame retardant performance is good and there are no harmful substances to the human body and the environment, it means the quality of the flame retardant cloth is better; conversely, the longer the burning time and the greater the degree of damage, the greater the flame retardant performance. No, the production of harmful substances indicates that the quality of the flame retardant cloth is extremely poor.

Method 2: Judge by the extreme oxygen index (LOI) of Oxford cloth burning. Theoretically, if the oxygen index of textile materials is above 21% (the oxygen concentration in natural air is 21%), the textile product will be self-extinguishing. According to the size of the extreme oxygen index, fabrics are usually divided into flammable (LOI less than 20%), combustible (LOI equal to 20%–26%), flame-retardant (LOI equal to 26%–34%) and non-combustible (LOI> 35%) four levels.

When testing the flame retardant performance of the above four levels, the flame retardant function is weakened and the flammability is enhanced in order from large to small with extreme oxygen index. The above two methods are the more common standards for judging the flame retardant performance of fire-retardant Oxford cloth. Customers can customize Oxford cloth with different flame retardant effects according to their own needs.

Independently research and develop flame-retardant fabrics. According to different requirements of customers, the following specifications are available: 210D, 300D, 420D, 600D, 900D, 1200D, 1680D Oxford cloth, etc., which have temporary flame-retardant effect and semi-permanent It has both waterproof and flame retardant effects and durable flame retardant effects. It can also be equipped with waterproof, flame retardant, PVC/PU coating, silver coating, composite and other treatments according to customer needs. You can contact the online customer service on the web page or leave a message. We will meet all your needs with dedicated service!

</p