Conductive cloth is flame retardant.

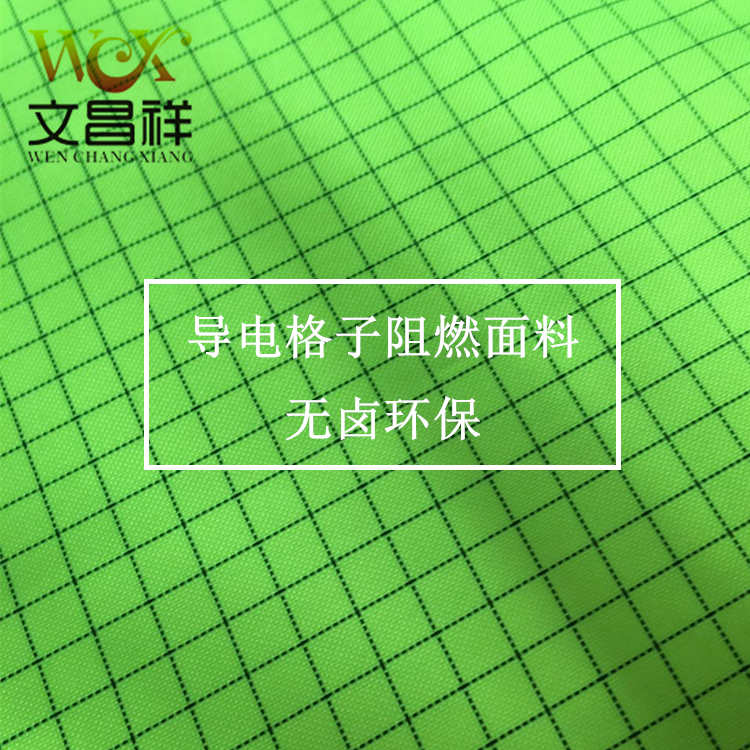

Conductive cloth is made of fiber cloth (generally commonly used polyester fiber cloth) as the base material. After pre-treatment, electroplating metal plating is applied to make it have metallic properties and become conductive fiber cloth. It can be divided into: nickel-plated conductive cloth, gold-plated conductive cloth, carbon-plated conductive cloth, aluminum foil fiber composite cloth. The appearance is divided into plain and mesh.

The main material of conductive fabric, also called anti-static fabric, is polyester + conductive fiber. The conductive fiber is carbonized or doped, and carbon black is mixed with the fiber material. The carbon black forms a continuous phase structure in the fiber, giving the fiber conductivity. Polyester is prone to static electricity. Adding conductive fibers makes the fabric conductive. The conductive fibers discharge the static electricity on the human body through the conductive threads.

So what are the functions of conductive cloth? Conductive cloth can eliminate the harm of static electricity to the human body and eliminate static electricity generated when people put on and take off clothes when exercising; it has excellent anti-static performance and is resistant to washing; in electronics, instrumentation and other industries, it can prevent damage and aging of electronic components caused by static electricity ; In the petrochemical industry, it can prevent dangers such as burning and explosion caused by static electricity. It can be used for professional shielding work clothes for high-radiation work such as electronics and electromagnetics, special shielding cloth for shielding rooms; special cloth for shielding parts in the IT industry, currently popular touch screen gloves, radiation-proof curtains, etc.

Conductive cloth has been widely used in national defense, aerospace, electronics, communications, medical, etc., to protect workers from microwave and high-frequency damage and reduce the impact of electromagnetic waves on electronic equipment that is disturbed by external electromagnetic waves. Environmental pollution.

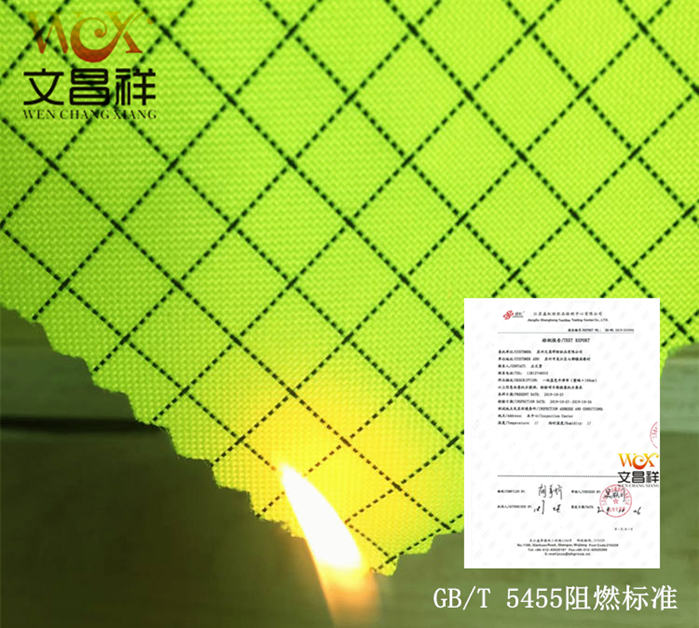

Independently research and develop flame-retardant fabrics. According to different requirements of customers, the following specifications are available: 210D, 300D, 420D, 600D, 900D, 1200D, 1680D Oxford cloth, etc., which have temporary flame-retardant effects. Semi-durable flame retardant effect and durable flame retardant effect can also be provided with waterproof, flame retardant, PVC/PU coating, silver coating, composite and other treatments according to customer needs. You can contact the online customer service on the website, or you can Leave a message and we will provide dedicated service to meet all your requirements. </p